Here I sit in anticipation of, not only our departure but the inevitable “How on earth did we forget that” moment which I’m sure will come. I think everything is ready, bar the fresh food, and with only 3 days to go I’ve started to think about the first passage plan.

For the non sailors among you, a Passage Plan is a requirement of the Skipper to make a written plan for the passage the boat is making. It should contain ‘adequate ‘ detail of navigational and safety aspects to get the boat from one place to another.

So what are the considerations for making a passage plan.

No 1 is probably the weather. Should you go out in the first place, is your experience good enough, is your boat sea worthy enough. How will the wind direction affect the time it takes for your passage. how uncomfortable or dangerous will this make the sea,

No 2 is tide. Tide is a magical thing it turns land into sea and sea into land, twice a day. Tides flow and sometimes and currents can be very fast indeed. Tide can be a game changer especially when sailing around headlands, these are often referred to as tidal gates. Sail boats always prefer to travel with the tide rather than against. It’s like cycling uphill or downhill, you all know which is faster or easier. Compromises often have to be made especially on longer journeys. Depth of tide also becomes important when leaving and entering port. and you must work out It there enough to keep your boat afloat.

No 3 The route, This is broken down into 3 parts.

- getting out from the harbour/river/anchorage etc, to the sea proper This includes obtaining permission to move, bouyage, channels, locks.

- getting from A to B, missing out sandbanks, rocks, shipping lanes, rough water areas etc.

- Locating, identifying and entering the destination port.

All the above are approached with a “What If” mentality to take into account, gear failure, illness, injury, weather changes.

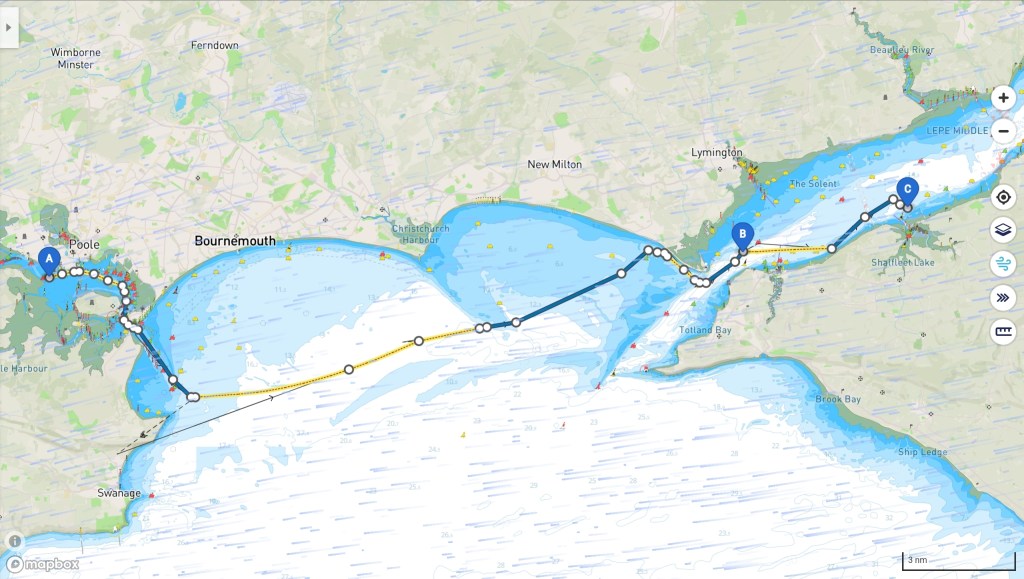

I was taught to use the appropriate charts, tide tables, tidal stream atlases and weather reports from the radio. You can, and in remote places away from the internet, have to do it this way, but modern day advances means apps on your phone or tablet can do it all far quicker. I tend to use an app called Savvy Navvy, which doe’s a lot of the heavy calculations for you. My preliminary route plan for Friday is shown below, this will be updated just before we go to take account of the latest weather report.

For fridays trip – From Wareham river to Newtown creek on the Isle of wight. There are a number of considerations.

A. Weather. The wind is coming directly from our destination, this will lengthen our trip by about 1/3

B The tide, the best time to leave Wareham will leave us with the worst time to cross from Poole to the Newtown Creek on the Isle of Wight. ie Tide against. This could add another hour or so to the journey.

So choices are to leave a little later, (more risk in a shallow river on a falling tide). Go at the original time and anchor somewhere for lunch to await a favourable tide, or as the wind is light and possibly unsailable. We could put on the iron sail. (engine) and motor against both tide and whatever wind there is.

So first option – rejected

Second option possible

Third option most likely.

Let’s see what conditions are like on the day. At the end of the day it’s only a plan and you often have to make dynamic decisions to account for unexpected conditions or events.